PV Inverter Technology Trends

release time:

2022-03-10

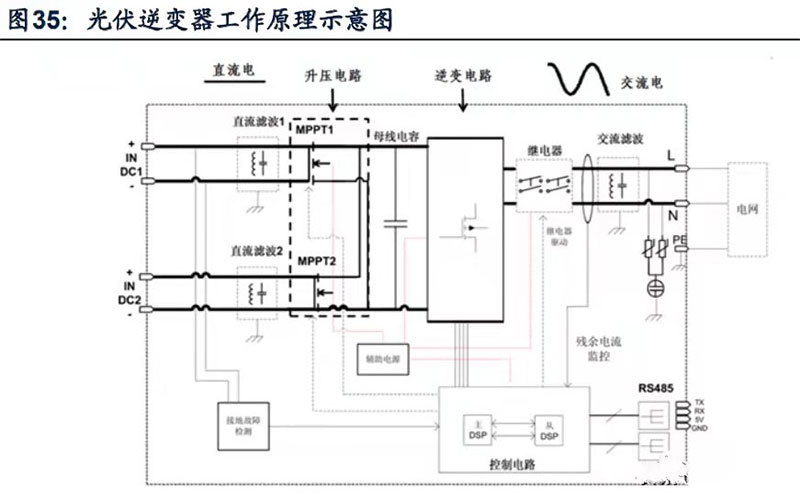

The photovoltaic inverter is the control center of the photovoltaic power generation system, which can convert the direct current generated by the components into alternating current for grid connection or load use. Photovoltaic inverter is mainly composed of power conversion module, microcomputer control module, EMI module, protection circuit, monitoring module, human-computer interaction module, etc.

(1) Technology trend 1: Power modularization accelerates string penetration, resonance between new and replacement demands

The photovoltaic inverter is the control center of the photovoltaic power generation system, which can convert the direct current generated by the components into alternating current for grid connection or load use. Photovoltaic inverter is mainly composed of power conversion module, microcomputer control module, EMI module, protection circuit, monitoring module, human-computer interaction module, etc. Its development depends on the development of electronic circuit technology, semiconductor device technology and modern control technology. All electricity generated by photovoltaic modules must be processed by the inverter before being output to the outside world. Therefore, the inverter belongs to the core BOS equipment of the photovoltaic power generation system.

Photovoltaic inverters can be divided into centralized, string and micro inverters according to their working principles. Due to the different working principles of various inverters, the application scenarios are also different:

(1) Centralized inverters first confluence and then invert, and are mainly suitable for large-scale centralized power plants with uniform illumination. The centralized inverter firstly fuses multiple parallel strings to the DC input end, and after the maximum power peak tracking is performed, it is then converted into AC power centrally, usually with a single unit capacity of more than 500kw. Due to the high integration degree and high power density of the centralized inverter system, the cost is low, and it is mainly used in large-scale workshops with uniform sunshine, desert power plants and other large-scale centralized photovoltaic power plants.

(2) The string inverter first inverts and then fuses, which is mainly suitable for scenarios such as small and medium-sized rooftops and small ground power stations. The string inverter is based on the modular concept. After the individual maximum power peak tracking of 1-4 PV strings is performed, the DC power generated by it is first converted into AC power, and then boosted and connected to the grid. Therefore, the power Relatively centralized type is smaller, but the application scenarios are more abundant. It can be applied to various types of power stations such as centralized power stations, distributed power stations and rooftop power stations. The price is slightly higher than that of centralized power stations.

(3) The micro-inverter is directly connected to the grid, which is mainly suitable for household and small distributed scenarios. The micro-inverter tracks the maximum power peak value of each photovoltaic module independently, and then merges it into the AC grid through the inverter. Compared with the previous two inverters, it has the smallest volume and the smallest power. It is mainly suitable for distributed household and small distributed industrial and commercial rooftop power stations, but the price is high, and it is difficult to maintain once a fault occurs.

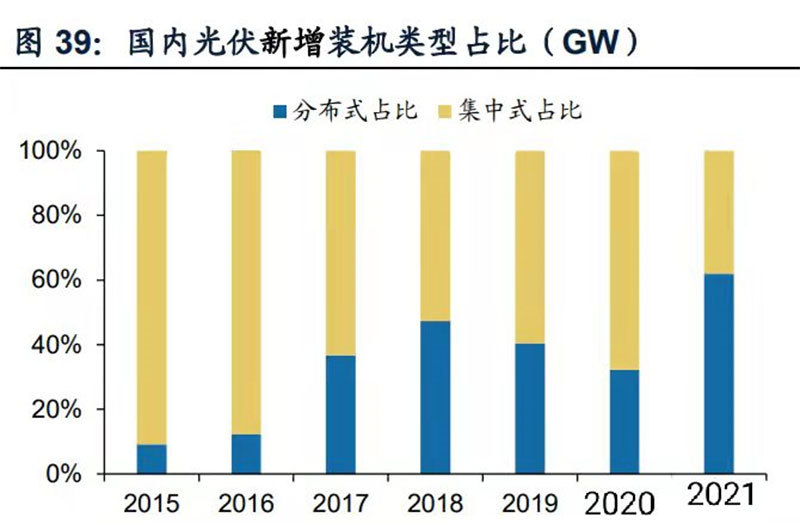

Benefiting from the increase in the proportion of distributed generation and the accelerated penetration of large-scale power plants, the market share of string inverters has gradually increased. According to GTM statistics, the global string inverter market share in 2019 was 52%, an increase of 11 pct compared to 2015. According to CPIA statistics, the market share of domestic string inverters in 2020 is 67%, an increase of 34.5 pct compared to 2016. The specific reasons are as follows:

(1) The string scheme is the first choice for distributed photovoltaic power generation, and the increase in the proportion will directly drive the increase in the share of the string:

The centralized photovoltaic power station has large investment, long construction period and large area, and is mainly built on large ground with uniform illumination. The centralized photovoltaic power station can make full use of the abundant and stable solar energy resources in the open space. Through the construction of large-scale photovoltaic power stations, it is connected to the high-voltage transmission system to supply long-distance recombination. power and agree to allocate power to users.

Distributed photovoltaic power plants have low investment threshold, fast construction, small footprint and flexible installation, which are the main directions of future photovoltaic development. Distributed power generation refers to the power supply system located near the user's location. In addition to the user's own use and nearby use, the power produced by it can also send excess power to the local distribution network. Due to the characteristics of dispersion and low energy density of solar energy resources, it has the natural advantages of distributed power generation. Due to the low threshold for centralized investment, the willingness of high electricity price users in parks, large industries, industrial and commercial sectors to utilize distributed power generation is increasing, which directly promotes the gradual increase in the market share of string inverters.

(2) The advantages of MPPT enabling and maintenance convenience of string inverters are obvious. With the increase of single-unit power, the gradually narrowing and centralized price difference will accelerate the penetration of the large-scale power station market: string inverters have high power generation and high reliability. , high safety, easy installation and maintenance, etc. When a module is blocked by shadows or fails, but because of the multi-channel MPPT, it will only affect the power generation corresponding to a few strings, which can minimize damage. The array mismatch loss is small and the efficiency is higher, and it is gradually applied in the large-scale power station market.

The main reason why string inverters have not been able to replace centralized inverters on a large scale before is that the cost is high, and the maximum power of a single unit is also limited by power devices and circuit layout. Iterative upgrades, the continuous development of superimposed power module technology, the continuous improvement of the power density of a single unit of string inverters, the rapid decline of prices, and the outstanding cost performance, more and more large-scale power plants choose to use string inverters. According to PV-tech statistics, among the domestic central SOE inverter centralized procurement projects announced in 2020, the bidding ratio of string inverters reached a new high, accounting for 74%.

The demand for "addition + replacement" accelerates the outbreak of the photovoltaic inverter market. Unlike the 25-30-year service life of photovoltaic modules, the service life of electronic components such as IGBTs used in photovoltaic inverters is generally 10-15 years, so the inverter needs to be replaced at least once during the operating cycle of photovoltaic power plants. In 2010 At that time, the new installed capacity of photovoltaics in the world has reached 17.5GW. As more photovoltaic power plants enter the period of technical transformation of the stock, the replacement demand will continue to grow.

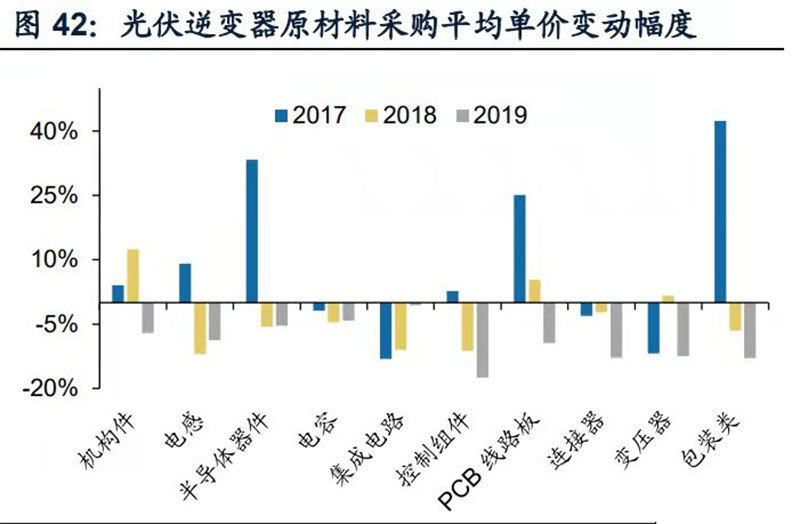

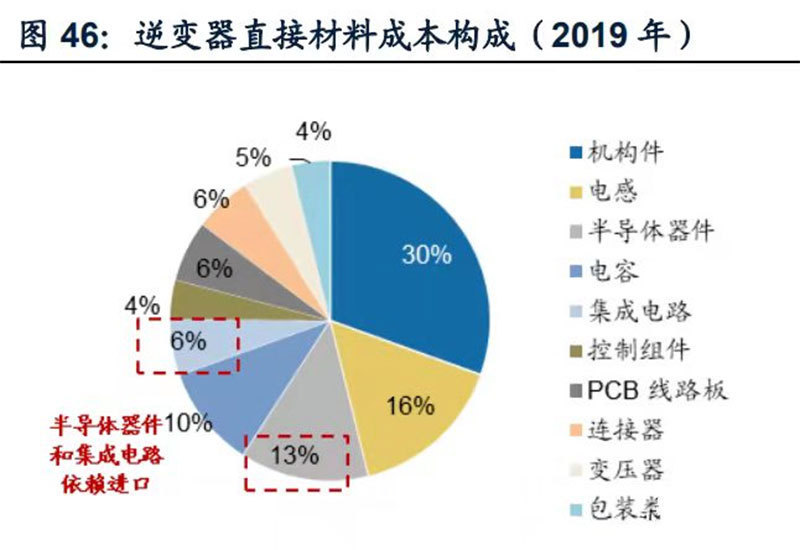

(2) Optimization space 1: The localization of the industrial chain superimposes technology upgrades and iterations, and domestic production accelerates going overseas

The rigid cost of raw materials for photovoltaic inverters is the core focus of cost reduction. The cost of raw materials for photovoltaic inverters accounts for more than 80%, mainly including electronic components, mechanical parts and auxiliary materials. Product pricing is mainly based on cost plus, brand positioning and comprehensive judgment on the local market competition situation. (1) The localization of the industrial chain drives the reduction of procurement costs: the domestic manufacturing industry has developed rapidly, most of the raw materials have been localized, the general-purpose materials market is fully competitive, and the purchase price has dropped year by year. Provided by overseas manufacturers, localization is expected to further reduce procurement costs. (2) Electronic and circuit technology upgrades help reduce costs and increase efficiency: In photovoltaic power generation applications, the cost of traditional inverters based on silicon-based devices accounts for about 10% of the system, but it is one of the main sources of system energy loss. The conversion efficiency of the photovoltaic inverter of the MOSFET power module can be increased from 96% to more than 99%, the energy loss can be reduced by more than 50%, and the cycle life of the equipment can be increased by 50 times, which can reduce the system volume, increase the power density and prolong the service life of the device.

Market penetration such as the United States and Japan still has potential for improvement, and the domestic inverter has a significant cost advantage, accelerating the optimization of the shipment structure overseas. Overseas markets have relatively high requirements for product performance and after-sales, and the competition atmosphere is relaxed. The inverters of photovoltaic power plants in countries such as the United States and Japan are still mainly provided by local brands; for example, two manufacturers, SolarEdge and Enphase, rely on technology and patent barriers, accounting for the US residential reverse. More than 80% share of inverters; Japan has a high entry barrier, and inverter manufacturers are mainly local companies such as TMEIC, Moron, and Panasonic. Due to the weak price sensitivity of overseas end customers, domestic inverters have a significant cost advantage, product performance is no longer inferior to imports, and the prices and gross profit margins of products exported overseas are significantly higher than those in China. Domestic inverter companies are accelerating their development of overseas markets. , continue to establish overseas channels and expand brand influence, the market share of Chinese inverter manufacturers among the top 10 manufacturers by shipments has rapidly increased from 13% in 2012 to 54% in 2020.

The output value of photovoltaic inverters will more than double in 2025, and the overseas market space will be broader. According to estimates, the global output value of photovoltaic inverters will reach 88.9 billion yuan in 2025, with a CAGR of 18% from 2020 to 2025, of which overseas markets will exceed 70 billion yuan.

(3) Technology trend 2: Energy storage is ready to go, empowering the emerging market of tens of billions of inverters

Inverters can be divided into photovoltaic grid-connected inverters and photovoltaic energy storage inverters according to whether energy is stored. The traditional grid-connected photovoltaic inverter can only perform one-way conversion from direct current to alternating current. It only generates electricity during the day, and the power generation is also affected by the weather, which has problems such as unpredictability. The energy storage inverter integrates photovoltaic grid-connected power generation. + The function of the energy storage power station, which stores the electric energy when the electric energy is abundant, and then inverts the stored electric energy and outputs it to the grid when the electric energy is insufficient, so as to balance the difference in electricity consumption between day and night and different seasons, and play the role of peak shaving and valley filling.

The integration of optical storage and storage is an inevitable trend, and policies should first promote the allocation and storage of new energy. Theoretically, in a completely photovoltaic power supply scenario, 1:3 to 1:5 energy storage is required to achieve uninterruptible power supply. The integration of photovoltaics and storage is expected to become a clean energy solution in the future. In the short term, the demand for energy storage installations is mainly driven by the policy side. Due to the impact of limited consumption space and power fluctuations, governments have accelerated the introduction of a series of relevant policies to encourage the energy storage market. Some domestic provinces and cities even mandated the allocation and storage of new energy. .

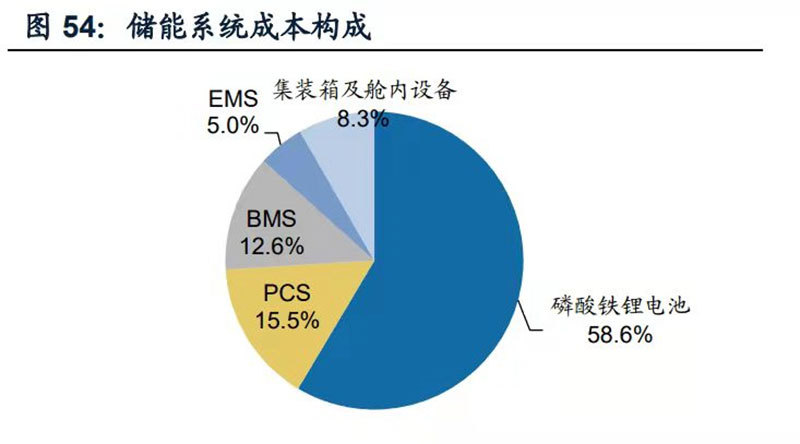

The cost decline has improved the economics of energy storage, and the parity of solar energy storage has stimulated the explosion of demand. In the long run, considering the volatility characteristics of new energy power generation such as photovoltaics and the cost of peak regulation and frequency regulation, new energy allocation and storage is an inevitable choice, and demand will shift from policy-driven to internal economy-driven. As the interface between the smart grid and the energy storage device, the energy storage converter (PCS) is mainly used to control the charging and discharging process of the battery in the energy storage system, and is responsible for the bidirectional conversion of AC and DC, which currently accounts for about 15.5% of the cost of the energy storage system , the cost of batteries is close to 60%. With the further exploration of the cost of the two, the demand for solar storage after parity will be driven by policy to spontaneously driven by internal economy. The energy storage inverter and the grid-connected inverter have the same technology. Although the protection circuit and buffer circuit are different, the hardware platform and topology are similar, so the cost reduction path is basically the same as that of the photovoltaic inverter.

Output value of energy storage inverters: The business models of energy storage are becoming more and more diverse, giving birth to an emerging market of energy storage inverters worth tens of billions. In grid-connected applications, according to the different links of generation, transmission, distribution and use of the energy storage system, it can be divided into energy storage on the generation side, energy storage on the distribution side and energy storage on the consumption side. The energy storage on the power generation side mainly solves the fluctuation and consumption problems of renewable energy grid-connected power generation, while the energy storage on the distribution side mainly realizes the function of peak regulation and frequency regulation. With the characteristics of large area and high investment cost, it is mainly used in large-scale centralized ground power stations and power grid substations. The power consumption side can be divided into household and industrial and commercial photovoltaic energy storage, which is mainly used to improve power generation revenue and reduce power consumption costs. According to the penetration rate of energy storage in various energy installed capacity ratios, it is estimated that the installed energy storage demand will exceed 140GW in 2025, and the output value of energy storage inverters will exceed 68 billion yuan, making the output value of the entire inverter industry exceed 150 billion yuan.

related news

2022-03-10

Jinan Aojia New Energy Equipment Co., Ltd.

copyright © 2022 Jinan Aojia New Energy Equipment Co., Ltd.

aojia_energy@163.com

aojia_energy@163.com

008615168886891

008615168886891